2023-03-06

Optimising conveying processes via brake control

RINGSPANN is implementing system solutions for easy synchronisation of conveyor systems

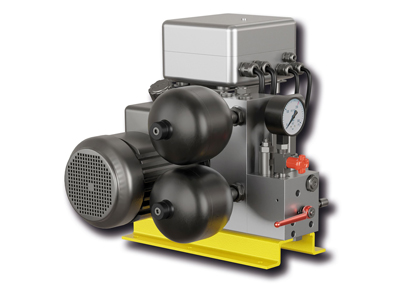

As a one-stop shop supplier for high-quality components in industrial drive technology, RINGSPANN is also implementing user-friendly system solutions for the controlled braking of heavy-duty conveyor systems. The technological core here is the innovative HCO-2R hydraulic power unit, which offers manufacturers and operators numerous possibilities for process optimisation. It can be combined with the company's hydraulic brakes and adjusted without the need for any programming on the part of the customer.

Bad Homburg, March 2023. – RINGSPANN offers a wide range of drum and disc brakes with clamping forces of up to 560 kN for use in the drivetrains of heavy-duty belt conveyor systems, such as those typically used in mining, bulk materials and earthmoving technology. Tailored specifically to this type of application, the company provides various system and monitoring modules that enables the implementation of intelligent complete solutions. The focus is always on increasing the degree of automation and simplifying operation. It is within this context that the HCO-2R hydraulic unit is becoming increasingly important, enabling both system manufacturers and system operators to optimise the belt conveyor processes in many ways through the targeted control of the brakes. The key aspect here is that the braking process is controlled solely by the physical value of the braking time, which considerably accelerates the entire setup work and reduces it to a minimum! Martin Ohler, the business developer for brake technology at RINGSPANN, explains: "Our system offers the unique advantage of being able to coordinate the braking processes of several conveyor belt segments in the shortest possible time and completely without any need for programming - regardless of their length, incline, belt speed and load. What used to be an enormous time and cost factor with all kinds of uncertainties for both operators and manufacturers of belt conveyor systems can now be accomplished in a matter of seconds."

One controller and many possibilities

With RINGSPANN’s HCO-2R, users are provided with a tool to adjust the brakes of their conveyor system without any programming knowledge required so that they can always react according to their needs. All necessary adjustments due to changing belt loads, fluctuating conveyor speeds, alternating load requirements or even changing between longer and shorter holding times at different material loading and transfer points are simplified in an almost radical way thanks to RINGSPANN’s own controlled braking design. "In every project our objective is to enable the customer to implement their intentions and ideas regarding process optimisation without compromise. In doing so, the unparalleled user-friendliness of our system solution gives them the ability to realise their ideas quickly, easily and at any time," says Martin Ohler. What this means in concrete terms can be seen not only in eliminating the need for any programming on the part of the customer, but also in the fact that the infinitely variable brake control is always designed in such a way that its manual operation on site is carried out merely via a single rotary potentiometer.

The time factor as a benchmark

Reducing it all to a single control element has been made possible because RINGSPANN’s engineering, in consultation with the customer, incorporates all relevant aspects of a conveying process in advance into the dimensioning of brakes and hydraulic unit. Specifically, this means that factors such as belt width, belt tension, number of belt sections, topographical conditions on site and many others are already factored into the specification of the brake system during the planning phase and are combined in the control factor braking time. This simplification benefits both the system manufacturer during the project planning of the conveyor system and the user during operation in practice.

Rapidly synchronise multiple belt segments

As standard, the operator of the conveyor system can regulate the braking time on the rotary control within a range of 20 to 40 seconds with high precision. However, other control ranges can also be pre-set on request. The interaction of the HCO-2R with the brakes from RINGSPANN opens up plenty of optimisation potential - beyond the process adaptations already mentioned - especially for the operators of complex conveyor systems with long transport distances. For example, expansive conveyor systems consisting of numerous belt segments with several independently operating drives and controlled braking systems can easily be synchronised with each other. And this all takes place independently of different conveyor speeds of individual belt segments or different loads and gradients!

Easy commissioning

Thanks to its simple operation, the RINGSPANN solution for controlled braking can be put into operation with minimal effort. In addition, the ability to easily and quickly configure even complex and long conveying processes proves to be a great advantage when modifying and reconfiguring conveyor systems. Depending on the situation, the use of the HCO-2R can even prove to be a sensible alternative to the integration of complicated and sometimes costly control system technology. “When clarifying this fundamental question as well as all further steps from project planning to commissioning on site, we are at the plant operator’s side as an experienced partner whose depth of expertise covers almost all aspects of industrial drive technology”, Martin Ohler emphasises. RINGSPANN not only offers a high-quality product portfolio that includes many basic components for the design of powerful and safe drives, but also possesses the engineering expertise - especially in the heavy-duty sector - to implement innovative system solutions. ms

System solutions and smart solutions

RINGSPANN is driving forward the expansion of its international presence as a one-stop-shop supplier for industrial drive technology components with a number of product innovations. Realising ready-to-install and multifunctional smart solutions and system solutions is also becoming increasingly important. Current examples of this are complete solutions consisting of shaft couplings and brake discs, shaft and overload couplings, torque limiters and belt pulleys as well as the brake systems with a control unit presented in the article. RINGSPANN’s objective is always to noticeably reduce the customer’s and user’s costs during assembly and operation.