2017-01-26

Ground-breaking solution with carbon

RINGSPANN presents brand new high-speed backstops with torque limiting

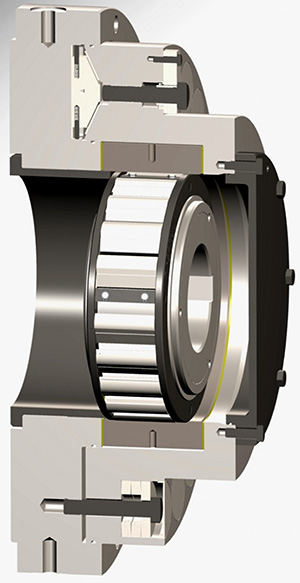

Manufacturer RINGSPANN has expanded its successful FXR series with new high-tech backstops featuring integrated positive torque limiters and a mechanical release function. What makes them so unique is the use of highly durable carbon friction linings that boast maximum surface pressure and, despite its compact size, make extreme slipping torques of up to 140,000 Nm possible. These backstops particularly open new prospects for safety and installation space optimisation for the design of multiple drives with fast running shafts – for example in conveyor technology.

Bad Homburg, January 2017. – The development engineers of RINGSPANN have realised a technological leap in performance with the new FXRW and FXRU high-speed backstops. They have managed to double the load-bearing capacity of the new backstops while maintaining or even reducing the previous outer diameter (330 - 975 mm). This was made possible thanks to the use of innovative friction linings made of carbon fibre, which offer maximum surface pressure with outstanding wear resistance. This allows the realisation of exceptionally high slipping torques – in extreme cases up to 140,000 Nm – in relation to size. The maximum slipping torque (MR) is – besides the expected maximum backdriving torque – the key parameter when designing a torque-limited backstop in multiple drives. It specifies the maximum load at which a backstop limits and takes effect to protect people and machine technology. In other words: the moment when it relieves peak torques and splits up uneven loads across multiple drive layouts.

More freedom for the design

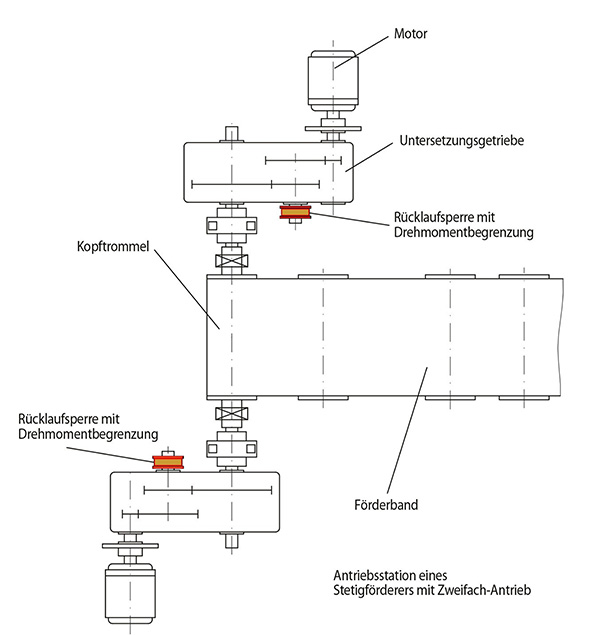

The new FXRW and FXRU backstops from RINGSPANN are high-tech design components for applications in gearboxes for multimotor drives. In freewheeling operation, the centrifugal forces that result during the rotation are cause the sprags to lift off from the outer track and ensure a wear-free operation. The new RINGSPANN backstops are, for example, suited to quickly secure running gearbox shafts of the first and second gear stages. Like all integrated freewheels of RINGSPANN’s FXR family, they also come equipped with integrated positive torque limiters as standard. Particularly for designers of multiple drive systems, this means: since the new backstops offer extremely high slipping torques in a relatively compact size, the safety standards of the drive systems can be significantly increased without taking up more installation space. It even offers the potential for more design freedom – for example regarding collision issues with neighbouring shafts or more cost-efficient gearbox designs.

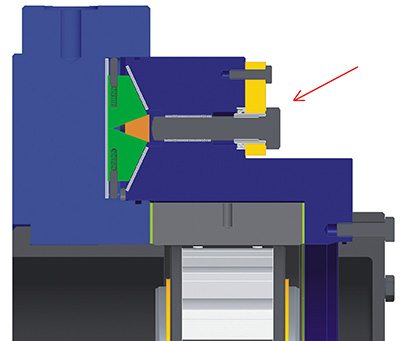

Another advantage of the new high-speed backstops of RINGSPANN is that the FXRU version is available in all sizes, and with a simple mechanical release function. Thanks to RINGSPANN’s patented release mechanics, you are not reliant on leak-susceptible hydraulic release systems. All this serves to make the operation of the new backstops even easier and to reduce maintenance costs.

Thanks to the simple release function and the very robust design as a whole, the new high-speed backstops from RINGSPANN are also ideally suited to dirty and dusty operating environments. A typical area of application, therefore, is in the multiple drive systems of conveyor systems in bulk goods, mining and heavy industries. Here, the backstops protect the built-in gearboxes against overload damages at different points of the installations thanks to what is usually a very uneven distribution of the arising load in the event of a reverse rotation – e.g. in the event of a shutdown or a sudden emergency stop. They also protect the entire drivetrain against dynamic peak torques.

Detailed simulations in advance

Prior to the development of the new FXRW and FXRU backstops, RINGSPANN carried out detailed torque simulations using modern analysis tools and intensive rounds of customer surveys. This led among other things to an optimised computation model, and to the realisation that the desires of the users for robust and user-friendly backstops with high slipping torques can best be realised using friction linings made from carbon. The new RINGSPANN high-speed backstops are currently available in a total of 20 versions for slipping torques ranging from 3,300 Nm to 107,000 Nm.