2024-07-03

Favourite status in mechanical engineering

The freewheels of the BM series from RINGSPANN score with their high installation flexibility

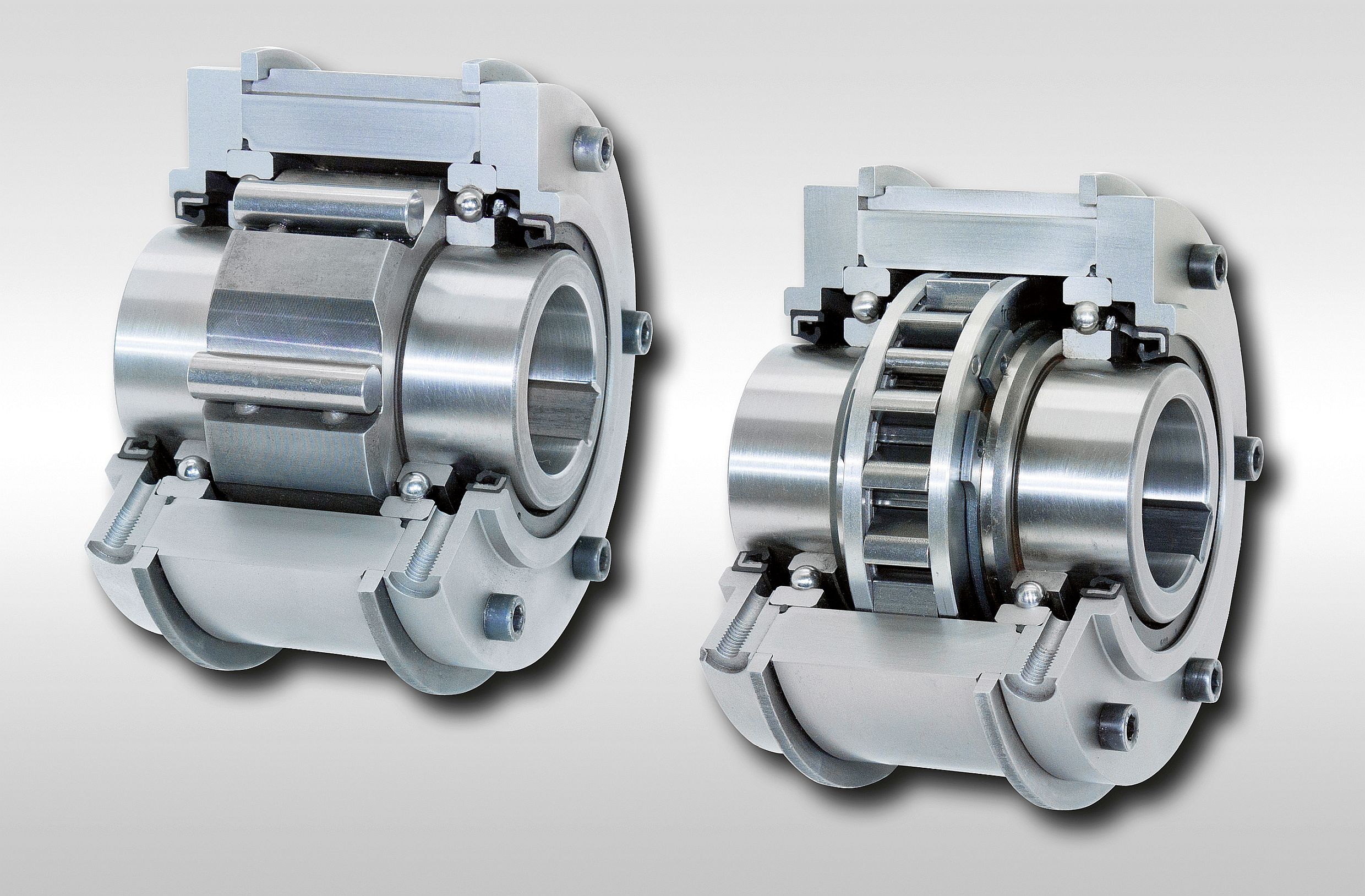

The complete freewheels of the BM series from RINGSPANN are among the favourites of designers in the international mechanical and plant engineering sector, in particular because of their versatility and their flexibility in terms of assembly technology. Designed as standard for nominal torques of up to 57,500 Nm, they are primarily used here as backstops in transmissions and as overrunning freewheels in multimotor drive systems. Read here about the practical added value they offer machine builders and their customers.

Bad Homburg, July 2024. – Many designers of high-quality drive systems for use in production machines and manufacturing plants opt for solutions from RINGSPANN's one-stop shop when selecting the necessary freewheels. The manufacturer’s complete freewheels in the BM series are currently enjoying particularly brisk demand from this segment of the capital goods industry. These are sealed freewheels on ball-bearings that are supplied oil-filled and ready for installation. They are available as standard in 19 sizes with bore diameters of up to 150 mm and for nominal torques from 150 to 57,500 Nm. Manuel Assmann, designer in RINGSPANN‘s freewheel division, also points out at this point that "the maximum transmittable torque of these freewheels is twice as high as the specified nominal torque, and that the versions with bores from 15 to 90 mm can be made available to customers at very short notice." With this alone, the company already covers a wide range of applications that are typical for mechanical and plant engineering. On closer inspection, it becomes apparent that the complete freewheels of the BM series are mainly used as backstops in transmissions and as overtaking freewheels in the powertrains of multimotor units. This means that the designers use them both for the implementation of safety and emergency stop devices (return/direction of rotation lock) and for the configuration of coupling solutions (overtaking/driving function).

Keyway-groove connection offers advantages

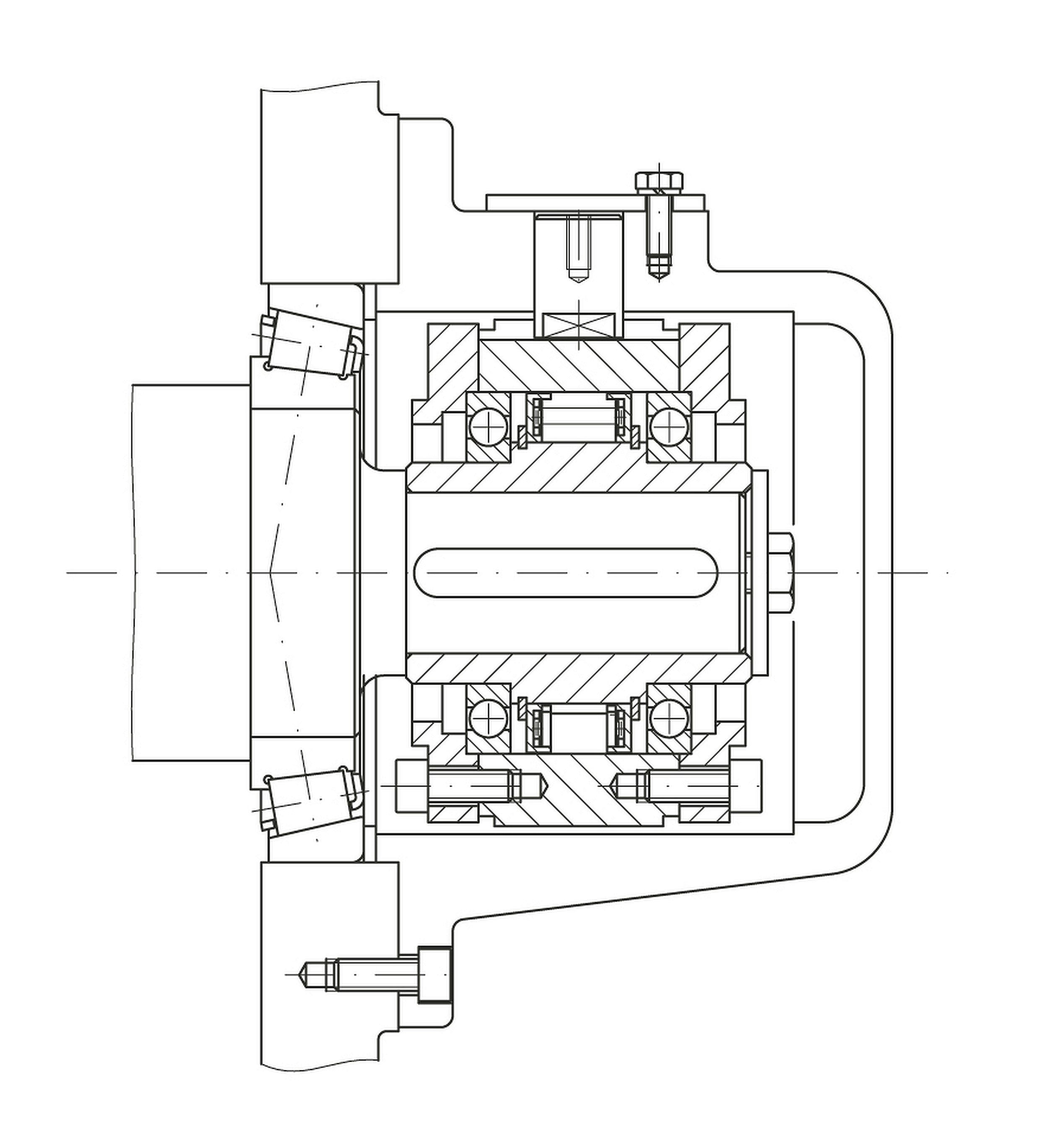

The particular attractiveness of RINGSPANN’s BM complete freewheels for drive technology applications in mechanical and plant engineering is based in addition on a number of crucial details of their design. Worth mentioning here is the keyway-groove connection on the outer ring of the freewheel. It offers three very specific advantages: versatile and uncomplicated integration of the freewheels into new and existing designs, installation effort reduced to a minimum and a high level of functional reliability. Manuel Assmann explains: "Our keyway groove connection simplifies the installation and removal of the freewheel. In addition, power is transmitted via a keyway groove milled into the middle of the outer ring. This ensures an even distribution of the forces acting on the freewheel, which gives it a high level of operational reliability and service life." However, if the customer prefers to use a radially sliding retaining bolt instead of the keyway solution, it can be pulled out during maintenance work so that the drive system can then be rotated backwards.

Clamping piece lift X as an alternative

Typical for RINGSPANN is that the ready-to-use complete freewheels of the BM series are also available in two basic versions with different clamping elements: in the standard design, they have clamping rollers – and are then also suitable as feed freewheels; in the second design, on the other hand, clamping pieces of type X specially developed by RINGSPANN work in their inside. Since these clamping pieces lift off the outer ring track of the freewheel due to their special geometry, as a result of centrifugal force in idle mode, BM complete freewheels fitted with them work largely wear-free and achieve a very long service life. "This applies to their use in backstop and overtaking functions and comes into play under the condition that the inner ring of the freewheel must follow a high shaft speed in idle mode, but the driving operation in the overtaking function runs slowly – which is quite typical for many applications in mechanical engineering," explains Manuel Assmann.

Typical applications of BM complete freewheels in mechanical and plant engineering include their use as backstops in helical gears or worm and screw presses, as components of the drive systems of sprockets, as overtaking freewheels for speed-dependent engagement and disengagement of the drive shafts of motors connected in series, and much more. In addition to the high quality and high availability of its service life-optimised, ready-to-install complete freewheels, RINGSPANN always offers its customers the option of configuring application-specific variants or implementing manufacturer-specific special solutions. ms

Speaking of housing freewheels

As the world market leader in freewheel technology, RINGSPANN also offers a wide range of housing freewheels. In order to simplify the selection and design process for designers, product developers and technical buyers at this point in its one-stop shop, the company recently launched a new online configurator. It guides users through all relevant data and selection options and is characterised by a calculation of the required torque, which takes into account the power data input and automatically determines the torque with the inclusion of a safety factor. After the calculation, the specified values are included in the product selection and result in a proposal for the appropriate housing freewheel. An inquiry can then be sent to RINGSPANN from the tool. Direct access to the configurator can be found via this link: Configurator for housing freewheels.